Introduction

Drones, also known as Unmanned Aerial Vehicles (UAVs), have revolutionized numerous industries, from agriculture to construction. They offer unprecedented capabilities in Surveillance, Land mapping, Inspection, and more.

In this blog, we explore the essential role of a drone motor as we delve into the concept of motor efficiency. Learn how motor efficiency influences critical aspects of drone performance, including flight time, power output, and heat management. Also, discover future trends shaping the landscape of drone technology.

What is a Drone Motor?

Motors are key components that empower aircraft to achieve flight by generating essential thrust. Working seamlessly with propellers and speed controllers, they ensure the drone’s movement and stability. Typically powered by electricity, these motors are predominantly brushless, offering enhanced efficiency, particularly in commercial drone applications. While brushed motors find utility in toy and mini drones, brushless motors dominate commercial projects.

Brushless DC motors offer low maintenance and non-sparking operation due to their absence of mechanical commutators or brushes. They also feature reduced shaft friction and inertia, minimized audible noise, and superior torque-to-weight ratios, enhancing power density and minimizing energy loss. Understanding the nuances of UAV motor specifications is crucial for enthusiasts, facilitating maintenance, upgrades, or custom drone builds.

Concept of Motor Efficiency

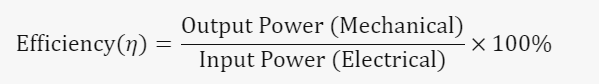

In the domain of electric motors, efficiency holds an essential role, serving as a vital metric for evaluating the proficiency with which these motors convert electrical energy into mechanical power. Represented as a percentage, efficiency indicates the ratio of useful mechanical output to electrical input.

Figure 1: Calculation of Motor Efficiency

For instance, a motor with 80% efficiency converts 80% of electrical energy into mechanical work, with the remaining 20% dissipated as heat. Motors boasting 90% or higher efficiency are deemed highly efficient, prioritizing energy conservation and output optimization.

Conversely, those below 80% fall into the low-efficiency category, consuming more energy and offering diminished performance. Understanding these efficiency levels aids in selecting motors aligned with specific requirements, with energy-efficient options delivering cost savings and environmental benefits.

Impact of Motor Efficiency on Drone Performance

The efficiency of motors is significant for optimal drone performance, impacting power output, flight duration, heat management, speed, weight, and battery usage. Hence, choosing highly efficient motors is a major element for peak UAV performance. Refer to the following points for a better understanding.

Power Output: Efficient motors play a pivotal role by converting a higher percentage of electrical energy into mechanical power. This directly influences drone flight performance, including speed, agility, and payload capacity.

Flight Time: Optimal for drones designed for extended flight durations, high-efficiency motors effectively manage power consumption, ensuring peak performance while maximizing flight time.

Heat Dissipation: Efficient motors minimize heat generation, contributing to overall performance and durability by preventing overheating. This is critical for preserving motor lifespan and preventing failure.

Speed: Torque-to-weight ratio is a key determinant of drone speed, particularly for high-speed models. Powerful and efficient motors contribute to achieving and maintaining high velocities.

Weight and Battery Consumption: While powerful motors may increase weight and battery usage, efficiency helps strike a balance. This leads to improved overall drone performance.

Motor Efficiency and Flight Time

The efficiency of quadcopter motors is also influential for flight duration. More efficient motors draw less current, conserving battery power for longer flights. While there isn’t a direct correlation, it is seen that highly efficient motors maintain performance while consuming less power, resulting in extended flight durations. This is important for missions requiring prolonged surveillance or mapping.

Optimal motor efficiency ensures maximum drone endurance and operational capabilities, making it essential to consider when selecting drone components.

Improving Motor Efficiency

Improving the efficiency of an electric motor for drones is essential for prolonging flight time and enhancing overall performance. Key strategies include:

a) Opting for brushless motors, which offer superior efficiency due to lower resistance and better cooling properties.

b) Propeller optimization involves experimenting with fewer blades and lower pitch design to identify the most efficient combination.

c) Utilizing a thrust stand aids in testing motors and propellers to determine the optimal setup.

d) Consistently flying at a steady forward speed rather than hovering reduces power consumption, leading to longer flight times.

e) Investing in high-capacity batteries provides more power without significantly increasing weight while reducing drone weight enhances overall efficiency.

f) Efficient cooling mechanisms, upgraded ESCs, and fine-tuned PID settings further contribute to maximizing motor efficiency.

g) Regular maintenance and monitoring are crucial for sustaining high-efficiency levels and ensuring optimal performance.

Future Trends in Flight Motor Efficiency

UAVs have brought about significant transformations in sectors ranging from agriculture to construction. India’s drone industry is poised for substantial growth, with government plans to establish the country as a leading global drone manufacturing hub by 2030. According to The Economic Times, projections indicate that the drone manufacturing sector in India could reach a value of US$ 4.2 billion by 2025, expanding to US$ 23 billion by 2030.

Globally, advancements in aircraft propulsion technology are evident, with a shift towards sophisticated motor control techniques like sinusoidal and field-oriented control, offering enhanced performance and stability. The surge in demand for micromotors is fueled by the rising popularity of small drones and UAVs.

Additionally, innovative developments such as collaborative drone systems and multifunctional drone designs, including ground-going tank-like drones and underwater deployable drones, are shaping the future landscape of drone technology both in India and worldwide.

Conclusion

In conclusion, rotorcraft motors are integral to the functionality and performance of unmanned aerial vehicles, driving advancements in efficiency and flight capabilities. Understanding motor efficiency is key for enthusiasts and industry professionals alike, as it directly impacts power output, flight duration, and overall drone performance.

As the drone industry continues to evolve, with India emerging as a significant player, advancements in motor technology will shape the future landscape, paving the way for enhanced efficiency, stability, and versatility in drone operations. Stay tuned, as we at Indrones continue to push the boundaries of innovation and efficiency in airborne motor technology.